HEAL B and B

Repairing Batteries for Enhanced Safety, Reliability, and Longevity

Overview

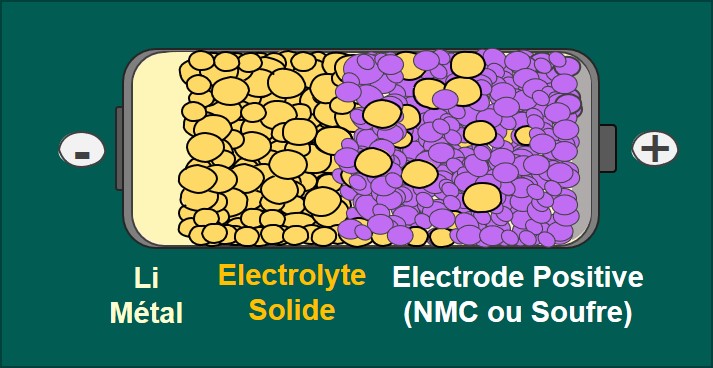

Integration of repair and monitoring functions to enhance the safety, reliability, and longevity of Li-ion batteries.

Christel Laberty-Robert (Laboratoire de Chimie de la Matière Condensée de Paris, Sorbonne Université)

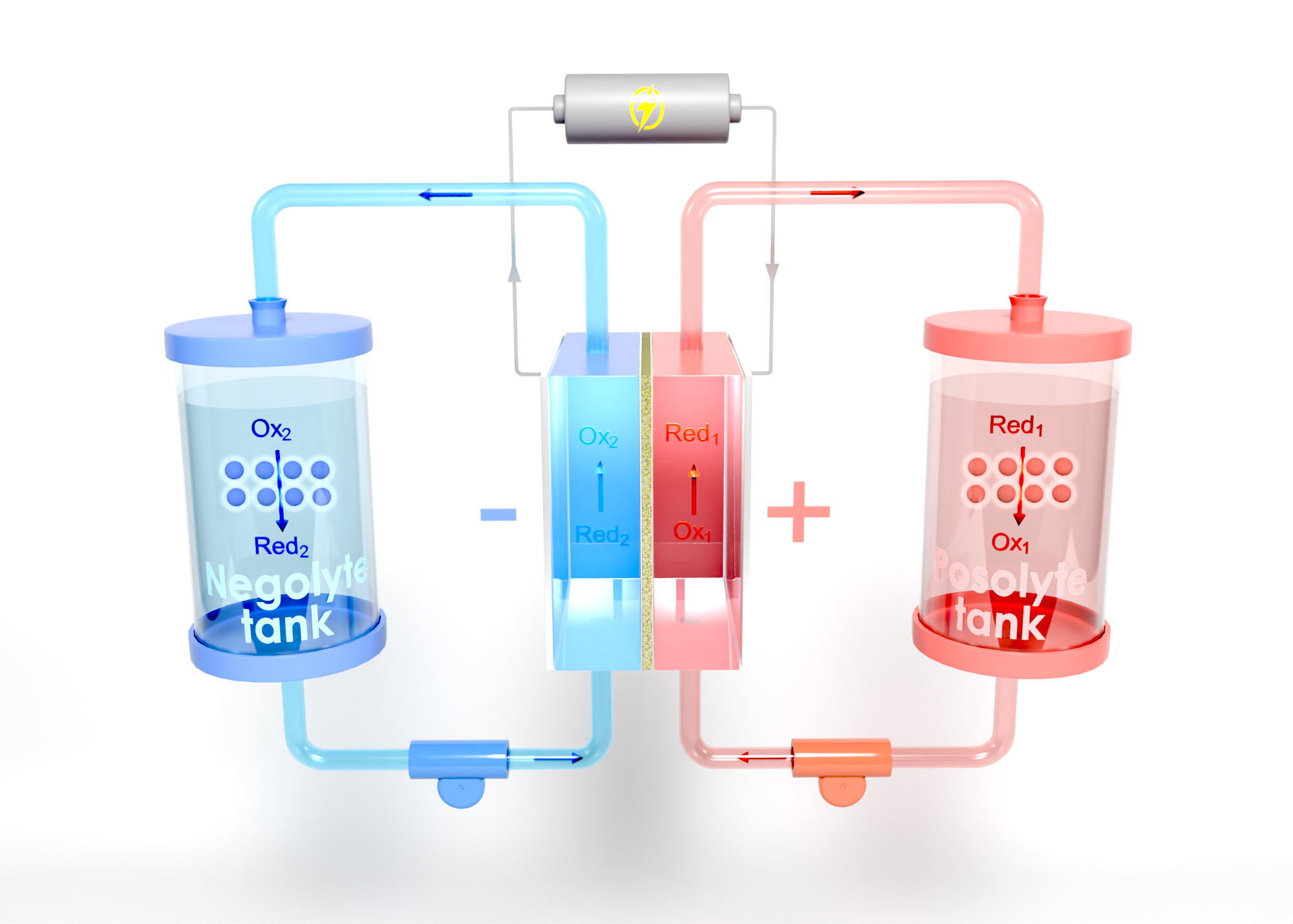

The Heal B and B project aims to enhance the safety, reliability, and longevity of Li-ion batteries by integrating innovative solutions around three main objectives:

I. Prevent: Design a functional binder with elastic and/or self-healing properties, and a functional separator capable of capturing degradation products.

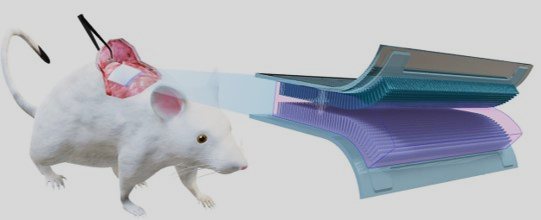

II. Detect: Integrate a sensor into the separator, connected to the battery management system (BMS).

III. Repair: Implement an on-demand repair strategy, controlled by the BMS, to restore the properties of the electrodes.

The Heal B and B project brings together expertise from specialists in processing, sol-gel chemistry (LCMCP), polymers (LPPI), and advanced battery characterization (IPREM, SyMMES).

Keywords

Repair, detection, functional separator, elastomeric binder, functionalized

Tasks

Our research

Prevent

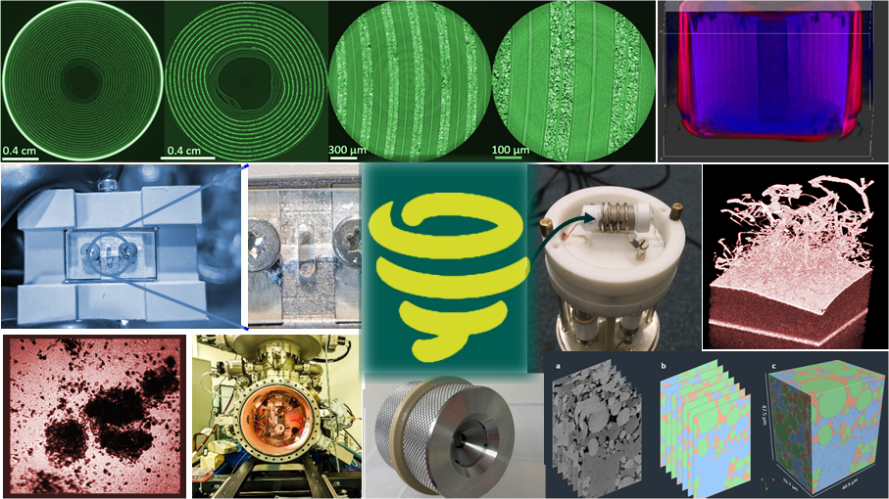

We will integrate several prevention strategies into the batteries using inert components. One of these strategies involves designing and integrating new functional binders into the positive electrode to maintain its integrity during charge and discharge cycles. By using electrospinning for separator fabrication and sol-gel chemistry, we will introduce chemical functions onto the separator fibers to capture decomposition products present in the electrolyte. These innovations will enhance the performance and durability of the batteries.

Detect

Our strategy involves integrating a reference electrode into the separator, enabling real-time monitoring of electrode conditions to track and quickly detect failures.

Répair

We plan to integrate on-demand repair features into battery cells to address component failures and enhance cell safety. Repair components will be stored within an electrospun separator designed with core-shell fibers. Their distribution will be triggered by an alternating current signal controlled by the battery management system (BMS) and activated by a third electrode embedded in the separator. This third electrode can also serve as a lithium reservoir, enabling the regeneration of defective electrodes.

The consortium

4 academic laboratories

The primary focus of the Heal B and B project is to test autonomous and on-demand repair concepts in conventional Li-ion batteries to enhance cell safety and quality without compromising performance. For on-demand repair, strategies will be explored for delivering lithium salts, organic molecules, and flame retardants. These innovative approaches will leverage polymer synthesis chemistry and the integration of chemistry with processes to design and synthesize new materials, such as functional binders and separators. Meanwhile, understanding of repair mechanisms will be deepened through the use of advanced characterization techniques.

The results obtained from the HEAL B and B project will contribute to enhancing the reliability, longevity, and safety of batteries.

Training of 4 PhD students and 4 postdoctoral researchers.